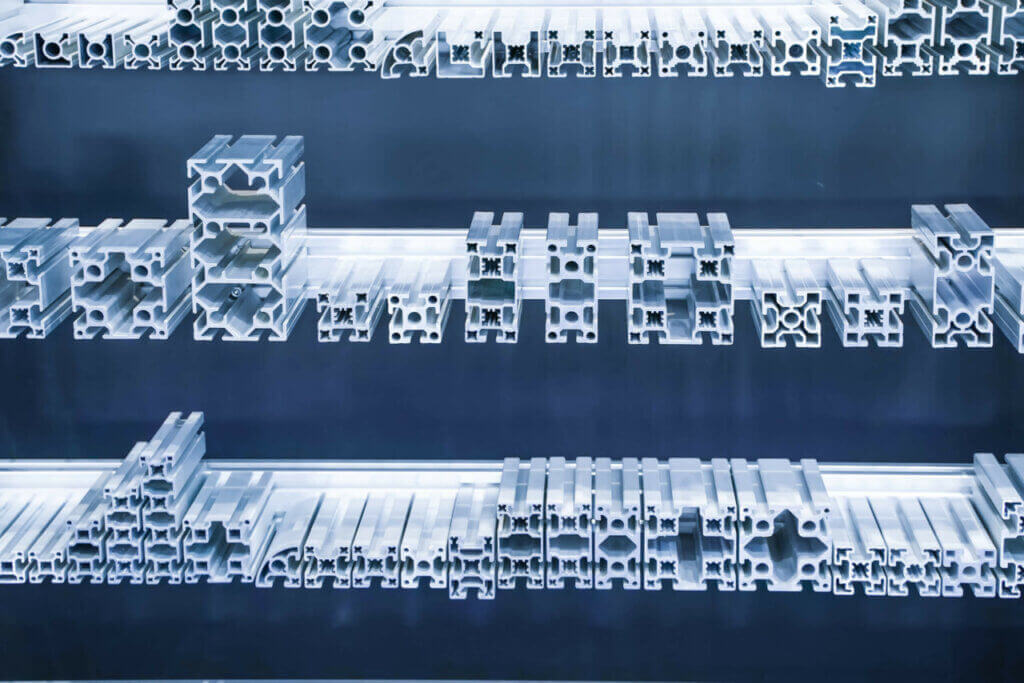

Nectar Incorporation offers comprehensive value-added services, including multiple secondary operations and custom finishes for your aluminum alloy extrusions.

At Nectar Incorporation, we manufacture high-quality extrusions with complex cross-sections produced using a range of aluminum alloys. We cut the aluminum extrusions to length and perform all necessary secondary operations, such as CNC machining and surface treatment. To submit part drawings, 3D files, and other relevant information, please click on the button below.

Applications of Extruded Aluminum

Extruded aluminum is a versatile material used in various industries:

- Automotive Industry: Ideal for manufacturing auto parts like engine blocks, transmission housings, and vehicle and truck bodies.

- Telecommunications: Suitable for housing copper or fiber optic cables or wires.

- Building and Construction: Extruded aluminum components resist distortion caused by weather and building movement, maintaining strength and flexibility under loads and recovering from impacts.